Location:

PMKI > People

Skills & Qualifications > PM

Training & Qualifications >

PMP Credential Training.

- PMP Overview

- Why we stopped teaching PMP

- PMP Exam Resources

- PMP Training Options

- Maintaining your PMP

(earning PDUs)

- Useful External Web-links &

Resources.

Other related sections of the PMKI:

- PM resources based on the PMBOK®

Guide

- Mosaic's training options

The PMP credential serves as an

unbiased endorsement of your project management knowledge

and expertise. It identifies you to employers as a

practitioner who has demonstrated competency in project

management processes and knowledge. PMI's Credentials are

recognized globally.

The PMP credential serves as an

unbiased endorsement of your project management knowledge

and expertise. It identifies you to employers as a

practitioner who has demonstrated competency in project

management processes and knowledge. PMI's Credentials are

recognized globally.

Obtaining your PMP, along with over one million other professionals worldwide, can go a long way toward enhancing your employment and getting you recognized in the workplace. Completing the PMP program enables individuals to come away with knowledge of tools and techniques to immediately improve project performance. Organizations benefit by developing a pool of highly knowledgeable project managers.

The only significant difference between the CAPM and PMP credentials is the eligibility requirement - they are both difficult exams:

'Directing and Leading' others means you role description is similar to 'team leader', 'test manager', 'senior analyst', or virtually any management role associated with the oversight of a project (or projects). Importantly you do not need to be the 'project manager'; although, of course, project managers qualify.

There are differences in the course materials to deal with the different examination specifications. The CAPM requirements are fully contained in the PMBOK® Guide. The PMP requirements are defined in the PMP examination specification, with the PMP examination incorporating some additional aspects of general management, including an expanded focus on 'Agile' and hybrid project delivery processes. There are also some minor differences in the style of the examination questions. The CAPM examination is 150 questions in 3 hours, the PMP exam is 200 questions in 4 hours.

Given the examinations appear to be of similar difficulty, our recommendation is to sit for the PMP exam if you are eligible - there is no point in taking the CAPM exam in preparation for the PMP exam later. However, if you are not eligible for the PMP examination, the CAPM exam does provide a good starting point for your career development, with a view to taking the PMP in 3 to 5 years time - see more on CAPM.

Click through for self-study resources based on the PMBOK® Guide

Scroll down for PMP Resources and PMP Training Options.

In

2019, PMI announced a major change in the PMP exam. The

new PMP® Exam Content Outline radically reformed

the examination to reflect the diverse skills and

approaches needed by project managers to deliver outcomes

and value to their organizations. The new exam covers both

predictive (~50%) and agile/hybrid (~50%) approaches to

project management (the previous exam was 90%+

predictive); this change brought the Agile Practice Guide,

bundled with the PMBOK® Guide 6th Edition into

the exam.

In

2019, PMI announced a major change in the PMP exam. The

new PMP® Exam Content Outline radically reformed

the examination to reflect the diverse skills and

approaches needed by project managers to deliver outcomes

and value to their organizations. The new exam covers both

predictive (~50%) and agile/hybrid (~50%) approaches to

project management (the previous exam was 90%+

predictive); this change brought the Agile Practice Guide,

bundled with the PMBOK® Guide 6th Edition into

the exam.

This shift in the PMP exam is focused on supporting information technology and business organizations, reflects the needs of most current PMI members, and should be applauded. However, from our perspective, the shift is moving the core of the exam into areas we have no specific skills in. We have never managed an 'Agile' project, and do not like presenting courses based purely on an academic understanding of its core content - basically you cannot teach an old dog new tricks.

These changes also affected the PMI R.E.P. program, which started in 1999, Mosaic Project Services Pty Ltd was a PMI R.E.P. from 2002 until 2020. However, updates to the R.E.P. program introduced in 2021 changed the focus from general training excellence to accrediting trainers delivering PMI developed PMP courses designed for the new PMP exam format; Mosaic does not offer the new PMP course and therefore was forced to withdraw from the R.E.P. program.. We still support the underlying approaches required of a R.E.P., while focusing on our core skill area of project scheduling and control where we still have core real-world knowledge and experience including:

When considering the PMP exam, the key documents you need to review are:

We update these regularly, but you need to check the PMI website for the latest version.

To retain your PMP status, you need to earn 60 PDUs every 3 years - see more on PMI's continuing certification requirements.

The art of learning and studying: The ability to learn is a skill that is exercised naturally by younger people, but as one grows older this natural ability seems to fade. This means assimilating the information needed to be successful in an examination is not easy, particularly if you have not studied for a while. To help, we have compiled a list of suggestions that may assist you to get back into the study mode and help with your exam techniques. See more on learning, studying, and exam techniques.

PMI Exam Questions: Success in the exam requires you to be good at answering questions which requires practice. But, simply studying questions and answers will never provide sufficient knowledge to pass your exam! See more on the role of questions in learning and for links to sets of free exam questions.

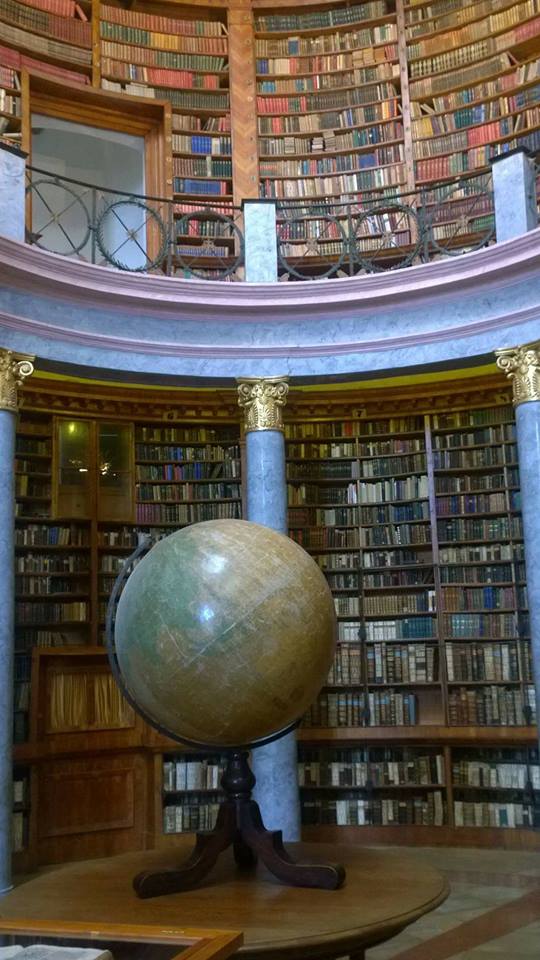

Mosaic's Project Management Knowledge Index (PMKI) is a ‘virtual library’, based around a defined taxonomy, designed to make valuable 'project management' information easily accessible both for use in the workplace and for use in exam preparation. Features of the PMKI library are:

Access to the library is completely free of charge and no registration of any form is needed to download our papers, the vast majority of which are available for use in study and/or the workplace under the Creative Commons 3.0 License.

Sections of the PMKI particularly relevant to the PMP exam include:

PM PrepCast PMP Course - https://www.project-management-prepcast.com/pmp-exam/the-pm-prepcast

Sybex PMP Exam Review - https://www.efficientlearning.com/pmp/products/platinum-review-course/

The Knowledge Academy - https://www.theknowledgeacademy.com/au/online-offers/pmp-online/

RMC Learning Solutions - https://rmcls.com/pmp

ILX Group Pty Ltd - https://www.ilxgroup.com/aus/individual/training/project-management-professional-pmp/pmp/online

Brain Sensei PMP Review - https://brainsensei.com/product/complete-pmp-exam-prep-course

OpenPM.org - An open Project Management Community, free PMP resources; exam simulators, PMP progress tracking & weekly exam questions (but remember self-study does not count towards the 35 hours of training required): https://openpm.org/

SimpliLearn - https://www.simplilearn.com/courses/project-management/pmp-certification-training

PMI's PMP Credential page: https://www.pmi.org/certifications/project-management-pmp

PMI's 'become a member' page: https://www.pmi.org/membership/join