Location:

PMKI > PM

Knowledge Areas > Quality Management.

- Quality overview

- Quality planning & standards

- Quality assurance & control

- Useful External Web-links &

Resources.

Other related sections of the PMKI:

- Risk management - uses

similar statistical techniques.

- Schedule quality assessment

Quality

is defined as: The degree to which a set of inherent

characteristics fulfill requirements This includes both

the stated and implied, needs and wants of the project

stakeholders. Quality requirements and expectations are

key inputs to properly defining the project requirements (see more on collecting

requirements). Requirements are fulfilled when the

product or service delivered is considered to be fit for

purpose, which encompasses:

Quality

is defined as: The degree to which a set of inherent

characteristics fulfill requirements This includes both

the stated and implied, needs and wants of the project

stakeholders. Quality requirements and expectations are

key inputs to properly defining the project requirements (see more on collecting

requirements). Requirements are fulfilled when the

product or service delivered is considered to be fit for

purpose, which encompasses:

It also means the product or service was created in a ‘quality work environment’ that met the needs and expectations of the people engaged in the creation processes (ie, the project team). Quality applies equally to both the management of the project and to the products delivered to external stakeholders (usually the client). It is nearly impossible to deliver quality outputs consistently and efficiently unless the work environment is of an equally high level of quality. Consequently, quality concepts apply to:

Quality

gurus:

Quality

gurus:

Six

Sigma, ISO 9000, other standards and methodologies.

Project quality management describes the processes

required to ensure that the project will satisfy the needs

for which it was undertaken. These processes include all

the activities of the performing organization that

determine quality policies, objectives, and

responsibilities. It focuses on implementing the project’s

quality management system.

Six

Sigma, ISO 9000, other standards and methodologies.

Project quality management describes the processes

required to ensure that the project will satisfy the needs

for which it was undertaken. These processes include all

the activities of the performing organization that

determine quality policies, objectives, and

responsibilities. It focuses on implementing the project’s

quality management system.

A quality standard specifies the requirements for a quality management system. To conform to the standard, the project needs to demonstrate its ability to consistently deliver outputs that meets customer requirements and applicable regulatory standards, by applying appropriate tools, techniques and approaches to the performance of the work. Methodologies for implementing quality including Six Sigma.

Six Sigma is a set of techniques and tools for process improvement. It seeks to improve the quality of the output of a process by identifying and removing the causes of defects (errors) and minimizing variability in manufacturing and project processes.

There is a subtle difference between compliance and conformance. Following your procedures correctly is conformity or conformance, not following them is nonconformity / nonconformance (ISO favours conformity, but the terms are synonymous). Procedures or products that meet externally imposed requirements (usually either regulations or contract obligations) are in compliance, procedures or products that do not meet said requirements are in a stat of noncompliance.

WP: Methodologies. Methodologies define a step-by-step series of processes for delivering projects or any other business outcome. Using an effective methodology reduces variability and increases quality.

WP: The value of Standard Operating Procedures. Developing and implementing effective SOPs to empower workers and enhance quality.

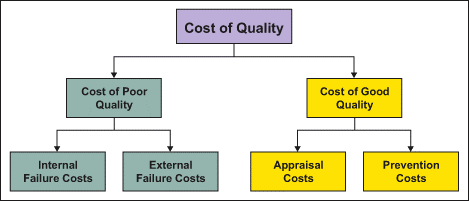

WP: Valuing Stakeholder Management (the Cost of Quality). The cost of quality has two main components; the cost of conformance (to achieve ‘good’ quality) and the cost of poor quality (or the cost of non-conformance), this paper looks at the decisions needed to obtain value from investing in 'good quality'.

Art: The Costs of Quality in Communication. Fit for purpose project communications and reports provide each stakeholder with the information they need.

Art: Ethics is not enough. Recent cladding fires demonstrate that achieving reliable quality standards needs more than simply relying on the ethical standards of everyone in the supply chain - the supply system needs to actively support ethical standards.

Understanding

the reliability of many products is important, in some

failure is totally unacceptable, in others knowing the

expected life of the component and having spare parts

available is adequate. FMEA is a methodology for

determining these factors.

Understanding

the reliability of many products is important, in some

failure is totally unacceptable, in others knowing the

expected life of the component and having spare parts

available is adequate. FMEA is a methodology for

determining these factors.

WP: Reliability and FMEA. A brief overview of the processes used to enhance reliability by analysing and removing sources of potential failure.

WP: V&V = the Verification and Validation of Deliverables. V&V should be a planned, on-going function that leads to the final acceptance of the project's deliverables by the client.

WP: Venn Diagrams. The use of Venn diagrams to display data and analise complex data sets.

WP: Root cause analysis. Techniques to assist in understanding the root cause of a problem including Ishikawa (fishbone) diagrams that look at cause and effect; and Toyota’s ‘Five Whys’ technique.

Art: Standard Deviation for Project Managers. The concepts behind Standard Deviation and how it is used.

WP: 14 point DCMA assessment (schedules). The Defense Contract Management Agency (DCMA) has developed a set of standards that (when met) ensure a well-built schedule. Each of the checks included in the DCMA 14 Point Assessment are discussed together with some additional useful checks from other sources.

ISO 9000 FAMILY - Quality Management: https://www.iso.org/iso-9001-quality-management.html